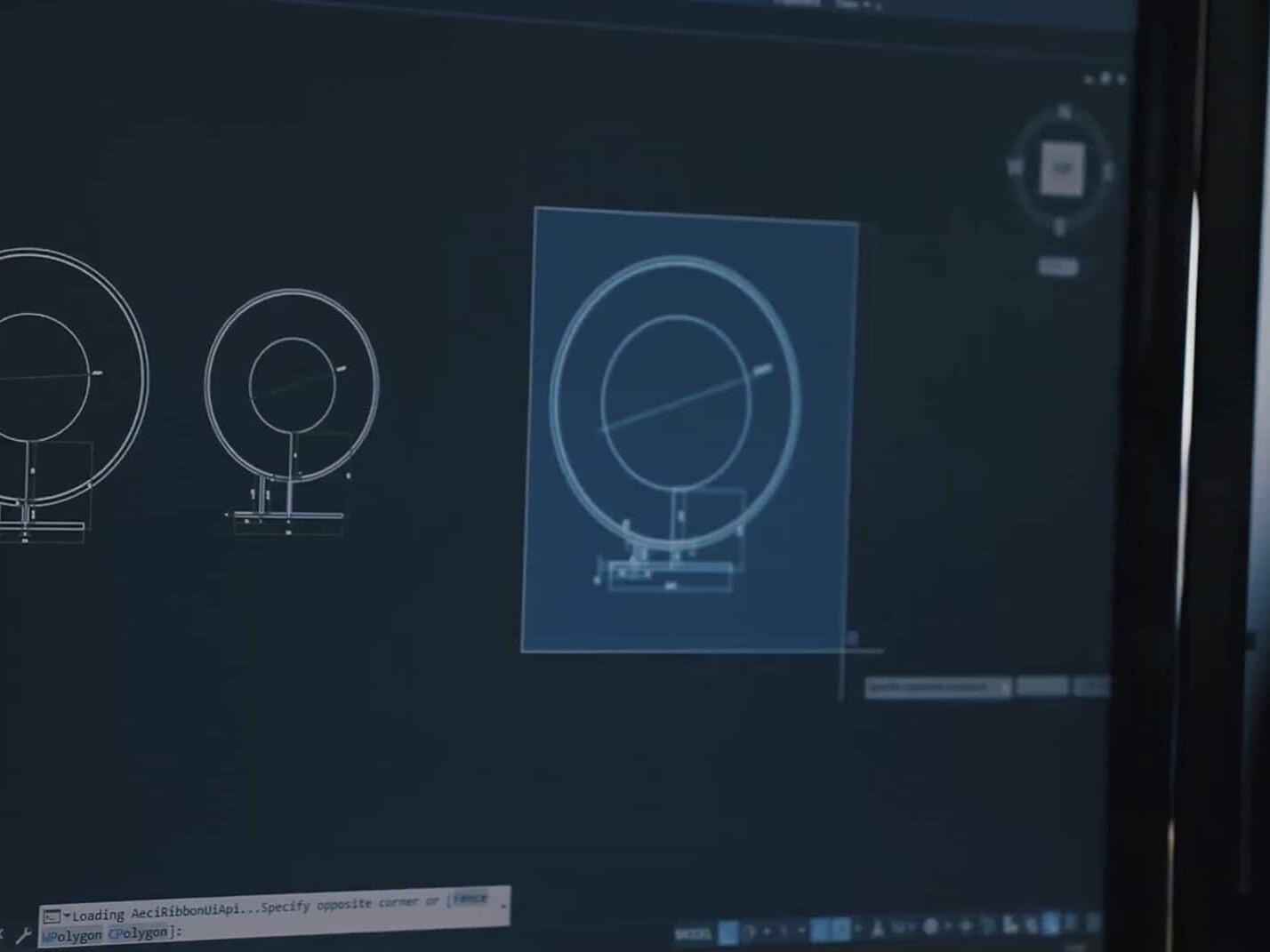

At Quality Pipe Supports (QPS) Ltd, we leverage advanced robotic welding technology to deliver precision, efficiency, and consistency in every weld. Our in-house Cobot Robotic Welder ensures exceptional results, minimising rework and meeting the exact specifications of our clients with unmatched accuracy.

Key Benefits

- Enhanced precision with automated torch movements.

- Consistent, high-quality welds that meet rigorous standards.

- Reduced rework, saving time and resources.

- Ability to handle complex projects with tight tolerances.

Our Approach

Our robotic welding system integrates cutting-edge technology and expertise to provide superior welding solutions:

- Precision Welding: The Cobot Robotic Welder performs precise torch movements, ensuring perfect welds every time.

- Automated Efficiency: Automation reduces human error and allows for faster project completion without compromising quality.

- Customised to Specification: Every weld is tailored to meet the specific thickness, materials, and design requirements of each project.

- Reduced Waste: Consistency in welding reduces the need for corrections, ensuring efficient use of materials and time.

Applications

Our robotic welding services are utilised across industries that demand high-quality and reliable welded components, including:

- Structural Steel Fabrication

- Pipe Support Assemblies

- Custom Manufacturing Projects

- Heavy-Duty and Industrial Equipment

Why Choose QPS for Robotic Welding?

- Advanced Technology: Our Cobot Robotic Welder represents the latest in welding automation.

- Proven Expertise: Decades of experience in delivering high-quality welded products.

- Efficient Processes: Automated systems ensure fast and cost-effective project execution.

- Custom Solutions: We adapt our welding techniques to meet the exact requirements of each client.